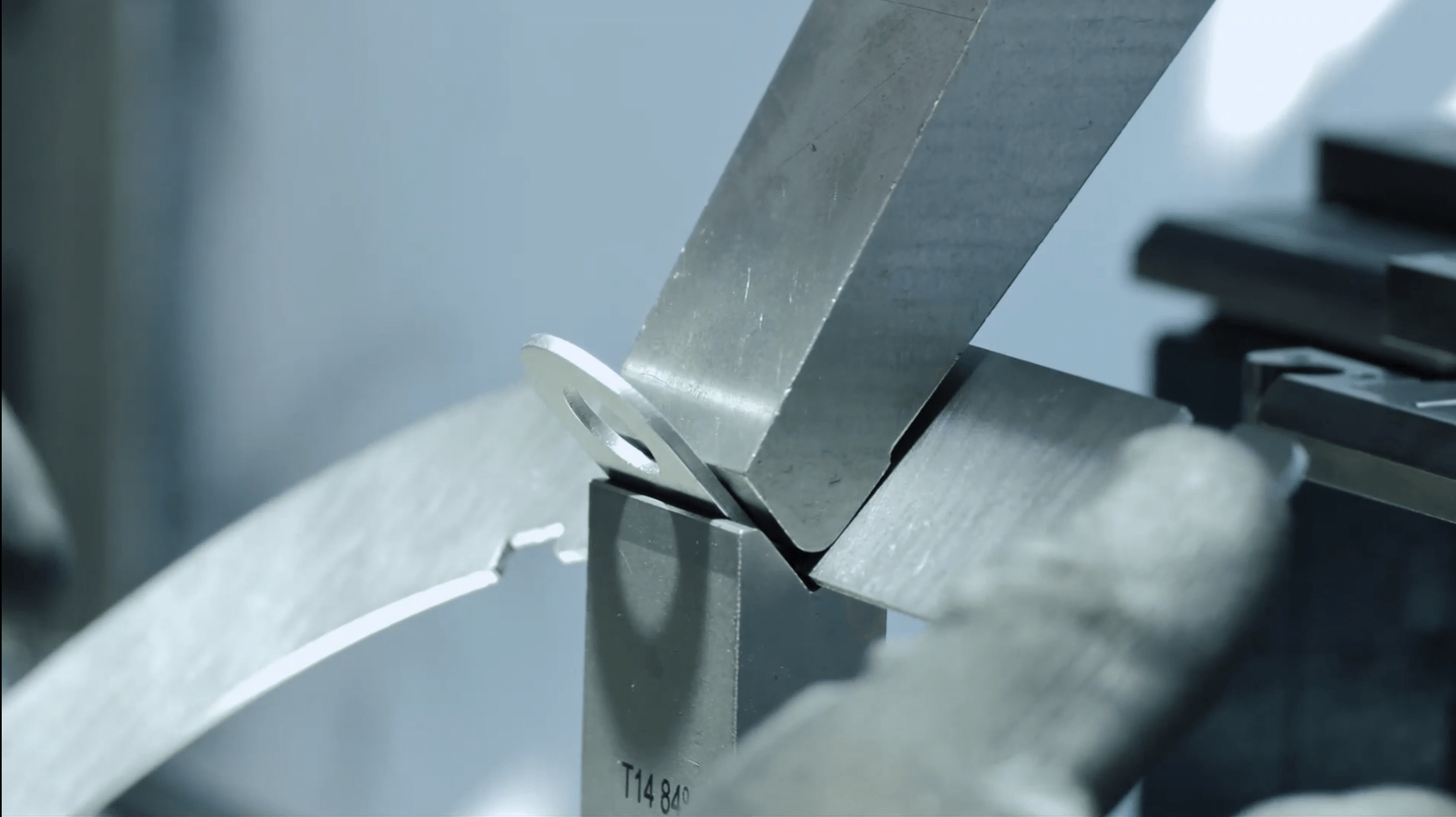

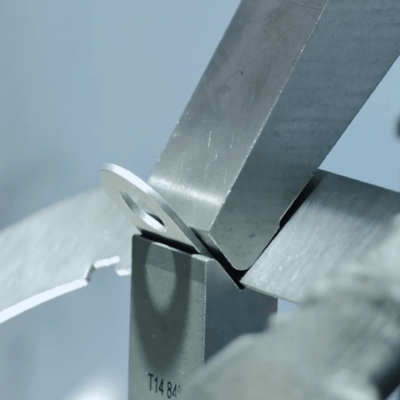

Precise bending with the use of press brakes which guarantees the repeatability of shapes and sizes

We provide sheet metal bending and rolling services. We guarantee 100% repeatability of the shape and dimensions of the performed elements

What technologies do we use?

For sheet metal b ending, we use modern CNC press brakes from one of the leading manufacturers in the market – Trumpf.

- The maximum pressure of our press is 230 t

- The maximum length of bending is 3000 mm

- Material thickness up to 12mm

- We program any bending angle with high accuracy of punch positioning (up to 0.005 mm).

Sheet rolling is made possible by our MG4R1006P/RR 4-roll, fully controlled rolling mill. The machine is capable of rolling parts with:

- Maximum length of 2m

- Thickness of 10 mm

- Minimum rolling radius of R150 mm.

In 4-roller machines, the rolled sheet is clamped between the driven upper and lower rollers, bending is carried out by moving side rollers. Such a structure minimizes the length of the straight section and ensures high precision of rolling. CNC control used in our machine allows the execution of complex shapes such as ovals, ellipses and guarantees high accuracy and repeatable execution of elements

Sheet metal bending and rolling in Merkson – comprehensive services

Merkson offers advanced sheet metal bending and rolling services, ensuring the highest quality and precision. Thanks to modern technologies and an experienced team, the company is able to meet even the most demanding projects. Sheet metal production is carried out using the latest machinery, which guarantees accuracy and repeatability.

Sheet metal rolling – precision machining

Sheetrolling is one of the key services offered by Merkson. This process makes it possible to obtain the right thickness and shape of metal parts, which is essential in many industrial sectors. Thanks to modern equipment, the company provides low-cost sheet rolling while maintaining the highest quality.

Sheet metal bending – advanced technologies

Sheet metalbending is another of the services that Merkson specializes in. Precise bending of metal parts is crucial for many applications, from building structures to machinery components. The company offers low-cost sheet metal bending, using advanced press brakes and an experienced team of technicians.

Comprehensive customer service

Merkson provides comprehensive service, from technical advice to order processing and final quality control. As a result, customers can count on low-cost sheet metal fabrication services and sheet rolling and sheet bending services that meet the highest standards.

Investment in modern technologies

Merkson continuously invests in modern technologies and the development of its employees. The pursuit of innovation and optimization of production processes allows us to offer customers the most efficient and cost-effective solutions. This makes it possible to maintain competitive prices while maintaining the highest quality of services.

Partnership with customers

Merkson is committed to long-term partnerships with its customers, offering a flexible approach and adaptation to individual needs. The company is able to handle both small and large orders, providing low-cost sheet metal fabrication services as well as low-cost sheet bending and low-cost sheet rolling.

Contact and information

To learn more about the services offered by Merkson, feel free to contact our sales department. The company’s specialists will be happy to answer any questions and advise on the best solutions.