Surface finishing after laser cutting, deburring and rounding of the edges, grinding

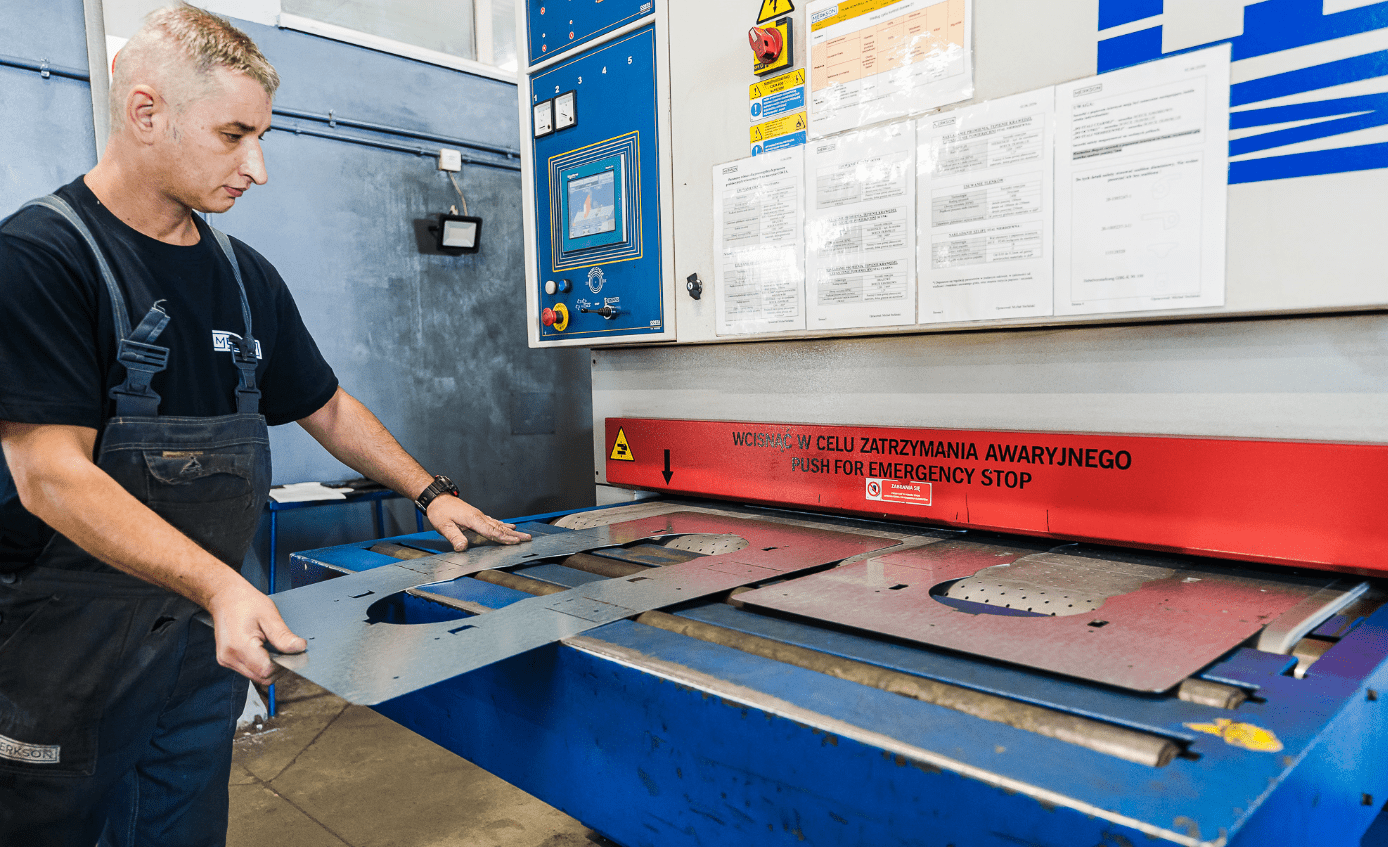

We currently have two machines for surface treatment of sheet metal and cut parts:

- COSTA MD 7, which we use for deburring, blunting edges and applying radius on black steel and stainless steel parts

- Q-fin Topgrinder, which we use for machining aluminum parts.

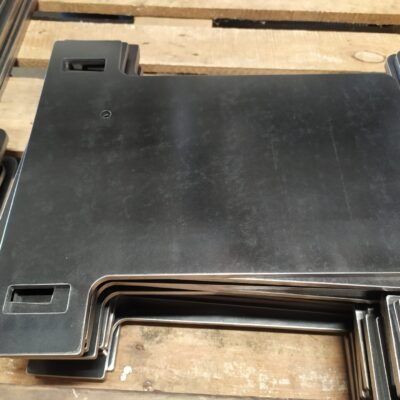

By removing burrs and rounding off the edges of parts, we offer workpieces that are perfectly prepared for further processing or anti-corrosion coatings, which are designed to meet stringent requirements for corrosion protection

- The maximum size of workpieces machined from black steel and stainless steel is 1200mm x 2000mm.

- In the case of aluminum, it is about 700 x1200mm.

Machining and surface finishing at Merkson – precision and quality

Merkson offers advanced metal surface treatment and finishing services, which is crucial to the durability and aesthetics of products. With state-of-the-art machinery and an experienced team, the company guarantees the highest quality workmanship.

Surface treatment technologies

As part of its services, Merkson uses modern metal surface treatment technologies. One of its main tools is the COSTA MD 7 machine, which is used for deburring, blunting edges and applying radius on black steel and stainless steel parts. The machine is capable of machining parts with maximum dimensions of 1200 mm x 2000 mm, ensuring precise and efficient processing.

Another advanced machine is the Q-fin Topgrinder, dedicated to machining aluminum parts. It allows precise deburring and edge rounding, which is essential to ensure safe use and prepare parts for further finishing processes. This machine is capable of machining parts with a maximum size of about 700 mm x 1200 mm.

Machining and finishing process

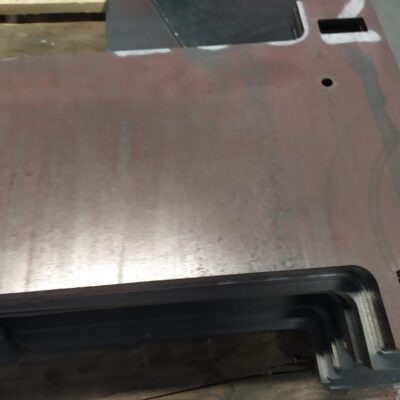

Merkson’s machiningand finishing process consists of several key steps. The first is deburring, which is the precise removal of sharp edges and irregularities created during cutting. This stage is crucial for making parts safer to use and preparing them for further processing.

This is followed by edge rounding, which involves giving the parts the appropriate radii. This process affects the aesthetics and functionality of the products and prepares them for further processes such as painting or anti-corrosion coating.

The final stage is the application of grinding, which is the imparting of the appropriate structure to metal surfaces. Grinding improves the appearance of the surface and prepares it for further finishing processes, such as painting or coating with various coatings.

Benefits of working with Merkson

Cooperation with Merkson brings many benefits. With its advanced machinery and skilled team, the company is able to provide the highest quality surface treatment. Merkson offers a wide range of services, covering various stages of surface treatment and finishing, which allows for comprehensive implementation of projects.

The company boasts many years of experience and numerous completed projects, which guarantees a professional approach and timely execution. The experience and commitment of the team ensure that each project is carried out with the utmost care and precision.

Contact us

To learn more about the metal surface treatment and finishing services offered by Merkson, contact our sales department. Our specialists will be happy to advise you and answer any questions you may have about our services.