All coatings are made in cooperation with reliable certified suppliers

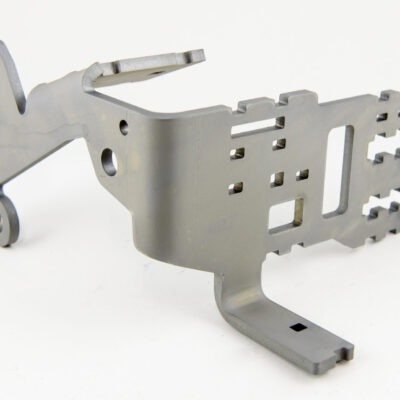

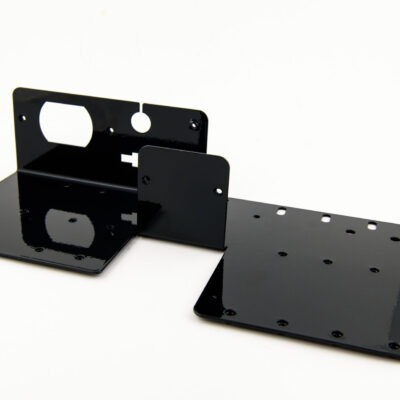

We offer components with coatings like:

- KTL

- Powder varnish

- Wet lacquer

- Zinc coatings

- Zinc-nickel alloy coatings

The components made by us and coated by our co-operators undergo positive, restrictive salt chamber tests:

- KTL -> min 240h

- KTL + powder coating -> min 480h

- Zn coatings -> min 480h

- Zinc-nickel coatings -> 480-960h

Anti-corrosion coatings – ensure the longevity of your products

Nowadays, corrosion protection is crucial to the durability and reliability of many products. Merkson specializes in providing advanced solutions such as anti-corrosion coatings.

Types of anti-corrosion coatings

At Merkson, we use several types of anti-corrosion coatings that can be applied to various components and surfaces. Here we can mention such ways as:

- KTL (Cataphoresis) – provides corrosion resistance for up to 240 hours in a salt chamber.

- Powder varnish – in combination with KTL guarantees protection for up to 480 hours.

- Wet lacquer – ideal for applications requiring a fine finish.

- Zinc coatings – offer resistance for up to 480 hours.

- Zinc-nickel alloy coatings – last from 480 to 960 hours.

Application of corrosion-resistant coatings

Anti-corrosion coatings are used in various industries, such as automotive, construction and marine. They enable structural components, machinery and vehicles to function without failure for many years. Each application requires specific protective properties, so Merkson offers a wide range of customized solutions.

Application process for anti-corrosion coatings

The application of anti-corrosion coat ings requires precise surface preparation and appropriate technological conditions. Merkson has a state-of-the-art machinery fleet that enables every stage of the process to be carried out according to the highest quality standards. As a result, customers can be sure that their products receive the best possible protection.

Quality control of anti-corrosion coatings

Every stage of the production process is subject to rigorous quality control. Merkson uses advanced testing methods, such as salt chambers, to ensure that the coatings meet the highest strength requirements. This ensures that the products are not only durable, but also safe to use.

Why Merkson?

Merkson maintains a production of more than 15,000 different components, which enables it to fulfill new orders quickly. With years of experience and cooperation with customers from all over Europe, Merkson provides customized solutions for each customer. The company relies on innovation and continuous improvement of its processes to maintain a competitive edge in the market.

Contact us

If you are looking for proven solutions in the form of anti-corrosion coatings, contact us The company’s specialists will be happy to advise you on choosing the right coatings and answer any questions.