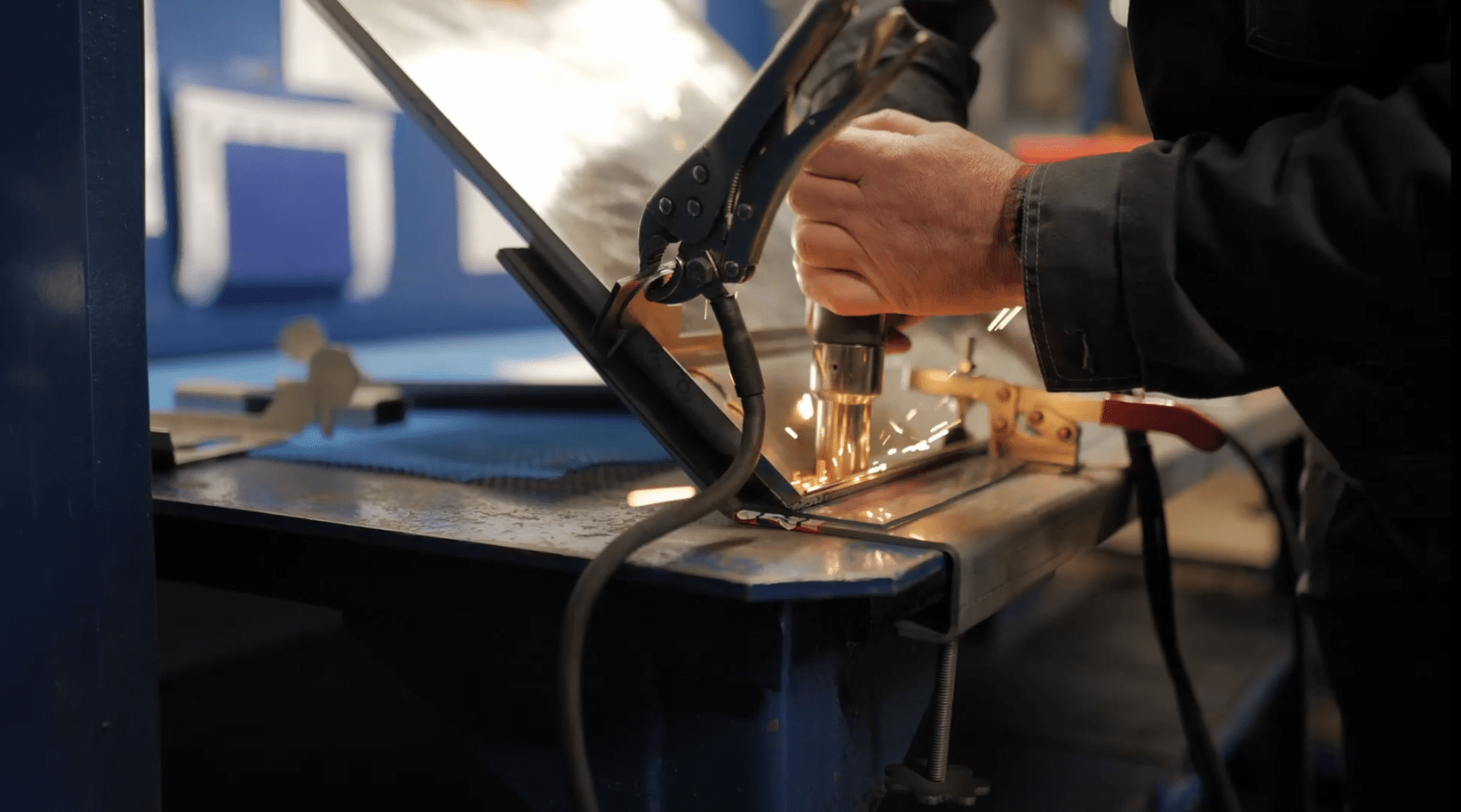

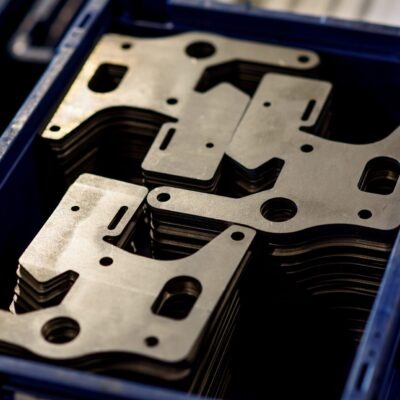

Welding and pressing in nuts, pins and the assembly of other fasteners

We perform nut and stud welding and spot welding of metal sheets. We have the capability to assemble press-fit fasteners such as nuts and PEM-type studs. On a daily basis, we assemble fasteners with thread diameters from M4 to M12. Our assembly offer also includes clinching, i.e. joining elements made of thin sheets by their point deformation. We use clinching technology to join metal sheets with a maximum thickness of 2mm + 2mm. We perform welding operations on stationary machines. We have two Pei point PFX 241 welding machines with inverter technology. We are able to weld:

- steel sheets up to 6 + 6 mm

- alloy plates up to 3 + 3 mm

- nuts according to DIN928 and DIN929 up to M12

We use a Haeger press for the assembly of press-in parts and clinching. We also perform the assembly of rivet nuts and rivet bolts with thread diameters up to M10.

Assembly in Merkson

Merkson offers advanced assembly services, providing comprehensive support for projects from the conceptual phase to final implementation. The assembly process begins with detailed planning that takes into account all technical and logistical aspects. A team of experienced engineers and technicians collaborates with the client at every stage to ensure that services are precisely tailored to individual needs and expectations.

Use of the latest technologies

When assembling metal components and structures, Merkson uses the latest technologies, such as assembly robots and automation systems, which ensure high precision and repeatability of operations. Thanks to its investment in modern technologies, the company is able to carry out even the most complex projects, while guaranteeing optimized costs and lead times.

Quality control and safety

Quality control is an integral part of every stage of the assembly process. Merkson implements rigorous testing and inspection procedures to ensure that each assembled component meets all requirements and is free from defects. All products are tested for durability, functionality and compliance with applicable norms and standards. In addition, Merkson prioritizes safety, ensuring that all health and safety regulations and procedures are followed during the execution of orders.

Merkson also offers on-site installation services, which is especially important for large and complex structures that require installation directly on site. Mobile installation teams are equipped with modern equipment and tools, which allows the installation to be carried out efficiently in all conditions. This makes it possible to minimize interruptions to the customer’s operations and quickly put the finished structure into service.

Investment in development and innovation in assembly

Merkson strives to continuously improve its assembly processes by investing in the latest technologies and training its employees. The pursuit of innovation and optimization allows the company to offer customers the most modern and efficient solutions. Employees regularly participate in training and courses to stay abreast of the latest trends and technological solutions in the industry.

Contact and cooperation

For customers looking for comprehensive installation services, Merkson is a partner you can rely on. The company combines advanced technologies, experience and commitment to perfection, which translates into the highest quality of completed projects. With an individual approach to each order, Merkson guarantees complete customer satisfaction.

We invite you to cooperate and contact our team, which will be happy to answer any questions and advise on the best installation solutions. Merkson company is a guarantee of quality, reliability and professionalism in the implementation of any installation project.