Designing and consultancy in the manufacture of metal sheet elements

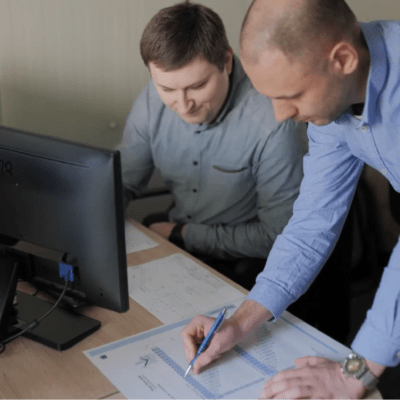

We offer design / preparation of 2D / 3 D projects for elements made of metal sheets. We also provide comprehensive advice on the technology of making the designed elements and the execution itself in accordance with the prepared project. Each project is available in 2D and 3D versions. Design service is available only when ordering a comprehensive service: design + execution

Design with Merkson – comprehensive services for industry

Merkson specializes in comprehensive design of sheet metal components, offering both 2D and 3D design services. Customers can count on support at every stage of the project – from technological consulting to execution in accordance with the prepared documentation.

Our services

Our company is primarily characterized by a multitude of different types of services including the design of sheet metal elements. For this we use such techniques as:

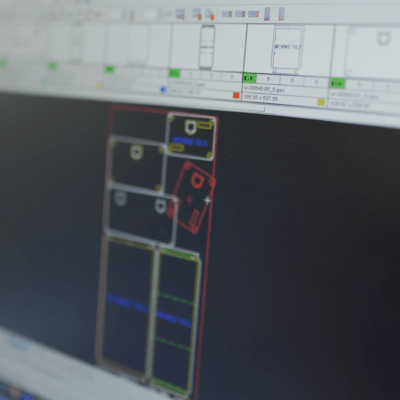

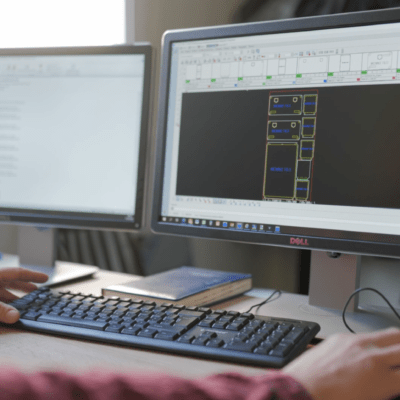

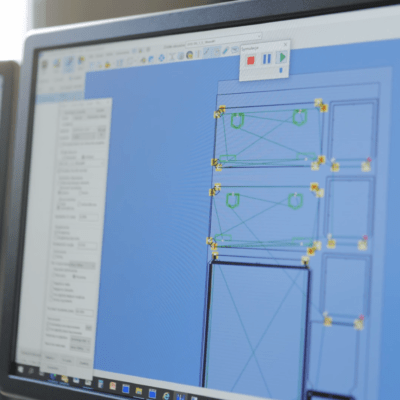

- 2D and 3D design – high quality customized designs, allowing precise reproduction of all details of the structure.

- Technological consulting – professional support in the selection of appropriate production technologies, optimization of processes to achieve the highest quality and efficiency.

- Comprehensive execution – implementation of projects from start to finish, covering all stages of production from concept to final product.

Stages of the design process

In order to properly implement the right design for the customer, we need precise guidelines. This process consists of several key stages that ensure that the final product will meet all customer requirements and expectations. This process will therefore include:

- Customer needs analysis – a thorough understanding of customer requirements and expectations, in order to tailor the project to meet specific needs.

- Concept and design – creation of concepts and detailed technical drawings, both in 2D and 3D, taking into account all technical and aesthetic requirements.

- Prototyping and testing – preparing prototypes and testing them to ensure full functionality and quality of the final product.

- Production and assembly – comprehensive execution of the production and assembly process, using modern technologies and materials of the highest quality.

- Quality control – rigorous testing and quality control at every stage of production, ensuring that the highest standards and customer requirements are met.

Advantages of cooperation with Merkson

Cooperation with Merkson brings many advantages. The company stands out in the market thanks to its many years of experience and extensive technical knowledge, which allows it to implement even the most demanding projects. A flexible approach to the specific needs of clients and adaptation to individual orders are important assets. Merkson uses the latest tools and technologies, which ensures the highest quality of sheet metal projects and efficiency of production processes. The company is also characterized by fast turnaround of projects and timely delivery of products, thanks to efficient work organization and advanced production technologies. In addition, cooperation with customers throughout Europe allows the company to provide services in accordance with international quality standards.

Contact

If you are looking for proven and professional design services, please contact our sales department. Our specialists will be happy to advise you and answer any questions.