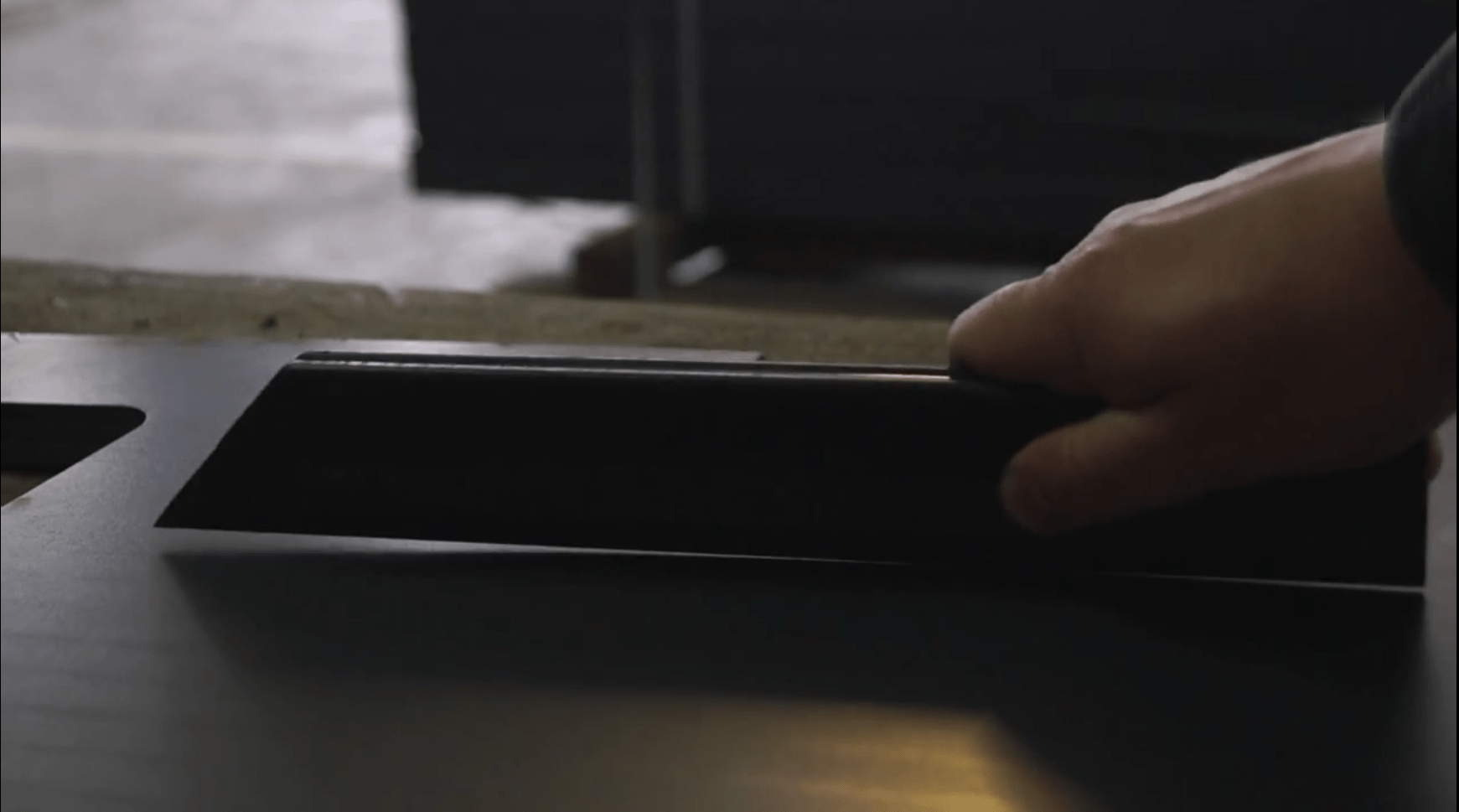

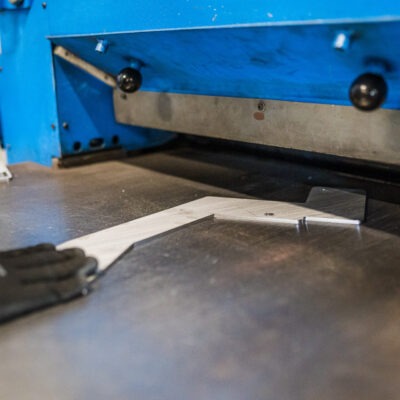

Straightening of parts and elimination of material stress as preparation for further working

Material deformation and lack of flatness are typical consequences of the laser cutting process, which are the result of local heating of the cut material. With the use of our HRC 50/750 straightening machine we are able to eliminate the resulting flatness defects in the thickness of the material from 0.5mm to 10mm and the maximum width of the straightened parts up to 750mm.Any stresses are released, making the performance of subsequent operations such as bending or welding is much more repeatable.Advantages of straightening parts after laser cutting:

- high flatness of the part

- internal stresses of the material are removed

- trouble-free further processing by bending and welding

- no additional costly finishing work and manual straightening

- high part quality

- low price

Straightening in Merkson – precision and accuracy in every detail

Merkson specializes in straightening services for metal parts, which is crucial for maintaining their dimensional accuracy and mechanical properties. The straightening process is essential for parts that have been deformed during heat treatment, cutting, bending or welding.

The straightening process

Metal straightening in Merkson is a complex process that requires specialized machinery and equipment, as well as the knowledge of experienced technicians. Thanks to modern equipment and advanced quality control methods, the company is able to straighten parts of various shapes and sizes, ensuring their perfect flatness and straightness.

The technology used by Merkson allows it to straighten parts made of various materials, including steel, aluminum and other metal alloys. The process is carried out using straightening machines, rollers and presses that precisely control the pressure to achieve the desired shape without damaging the material.

The importance of metal straightening

Metal straightening is extremely important in the production of components that must meet high quality and strength standards. Any deformation can lead to assembly problems, affect the functionality of final products and cause premature wear. Therefore, straightening accuracy is crucial to ensure the reliability and longevity of components used in various industries.

Applications of metal straightening in industry

Metal straightening services offered by Merkson are widely used in various industrial sectors. From the automotive industry to the construction industry to the engineering and energy industries, wherever precise and reliable components are essential, straightening plays a key role. Thanks to its advanced technology and experience, Merkson is able to meet even the most demanding orders, delivering products of the highest quality.

Quality control

In the metal straight ening process, quality control is extremely important to make sure that the parts meet all technical requirements. Merkson uses advanced inspection methods such as optical and mechanical measurements to accurately check the flatness, straightness and other key parameters of the parts. As a result, customers can rest assured that they are receiving products that meet the highest quality standards.

Contact and cooperation

Merkson offers comprehensive straightening services to customers in a variety of industries, ensuring precision, quality and on-time delivery. To learn more about cooperation opportunities, please feel free to contact our sales department. Our team will be happy to advise and answer any questions about our services.